Introduction: The aim of the study is to evaluate interfacial bond strength between silicone prosthetic elastomers and polymethylmethacrylate (PMMA).

Materials and Methods: Silicone elastomers were attached to PMMA and a total 120 specimens were fabricated which were then subdivided into 12 sub-groups. Each sample was then subjected to laboratory test to determine the bond strength. The specimen of silicone elastomer bonded to acrylic of different surfaces was placed into universal testing machine (HOUNSFIELD HT-400) for “PEEL TEST”. All the values obtained were tabulated and subjected to statistical analysis.

Result: The bond strength of silicone elastomer to acrylic resin (TRAVELON) noticed highest (Mean 4.826 ± 0.008 n/mm) when only primer was used as a surface treatment. When silicone elastomer bonded to acrylic resin (DPI) showed the bond strength of (4.351 ± 0.0089) when only primer was used as a surface treatment. Whereas the least bond strength values were found when the silicone bonded to acrylic surface treated by 120 grit sand paper that is (0.076 ± 0.00 n/mm) and (0.082 ± 0.01 n/mm) for DPI and TRAVELON respectively.

Conclusion: The bond strength of silicone elastomer to acrylic resin was higher when primer was used on the acrylic surface. The bond strength of silicone elastomer to acrylic resin was more with travelon resin when compared to DPI resin. But when silicone was bonded to acrylic surface with sand papering, showed less bond strength.

Introduction

Maxillofacial prosthesis is a rehabilitation of patients with defects or disabilities that were present when born or developed due to disease or trauma. Prostheses are often needed to replace missing areas of bone or tissue and restore oral functions such as swallowing, speech, and chewing [1].

Historical evidence of prosthetic restorations to replace the maxillofacial prosthesis was not found till sixteenth century where as copper and ivory was used as a facial prosthesis at a much later date [2].

The bond of silicone elastomer to the acrylic resin component must be rigid enough to withstand the forces acting upon the bond interface. Maxillofacial silicone elastomers and PMMA have different chemical structure, thus an adhesive is supplied to aid their bonding to the denture base. Adhesive primers have an organic solvent which reacts with both silicone and resin materials. The surfaces are activated via etching or promoting hydrogen bonding and covalent coupling, increasing the wet ability of the substrate and by impregnating the surface layer with the polymeric ingredients [3].

Gregory et al., conducted a study to evaluate the interfacial bond strength between different types of silicone facial elastomers and denture resin and they found that condensation silicone (cosmesil) always showed higher bond strength with three different types of denture resins compared to addition silicone (ideal) keeping other variables constant [4].

Rosita kantola, et al., did a study to check the adhesion of maxillofacial silicone elastomer to a fiber-reinforced composite resin framework and they concluded that bonding was improved when the fiber-reinforced composite resin was roughened through grinding which was bonded to maxilla-facial silicone elastomer by using primer containing methyl ethyl ketone and dichloromethane solvent [5].

Uttamsadashiv shetty, et al., evaluated the bonding efficiency between facial silicone and acrylic resin using different bonding agents and surface alteration and they concluded that a-330g primer was more compatible with cosmesil m511 silicone and has better bonding of cosmesil to acrylic resin [3].

Roy mcmordie, et al., did a study to check the effect of primer on bonding of silicone to denture base material. They used three primers to determine their effect on the strength of the bond when silastic 891 is cured to PMMA and concluded that the dow corning 4040 primer showed the greatest increase in bond strength [6].

Moodhy s Al-athel, et al., compared different test methods on the bond strength of silicone resilient denture lining material (molloplast-b) bonded to a PMMA denture base material. Cohesive failure of soft lining material during testing provides information regarding the material itself instead of an accurate measure of bond strength [7].

Omer kutay, et al., evaluated the bond strength characteristics of resilient liners by means of 180° peel test and butt tensile strength testing. Luciton 199 acrylic resin was used as a acrylic specimen. Seventy-two specimens were divided into peel bond and tensile bond specimen groups and were then subdivided into four test groups to evaluate each resilient liner. It was concluded that bond strength characteristics can vary according to the test method used [8].

Zafrulla khan, et al., compared the adhesion of resilient lining materials to triad visible light-cured denture base material. The liners used were tru-soft, molloplast-b, and esscheem. They concluded that all of the materials tested bond sufficiently to triad to be considered clinically acceptable [9].

ER Dootz, et al., compared physical properties of 11 soft denture lining materials as a function of accelerated aging. They concluded that accelerated aging dramatically affected the physical and mechanical properties of many of the elastomers, there is a wide range of physical properties for soft denture lining materials, no single soft denture lining material proved to be superior to all others, essential physical properties required for soft denture lining materials have not been defined [10]. The data obtained in this study would support the development of a specification for soft denture lining materials.

Thomas J Emmer, et al., did a study to check the bond strength of permanent soft denture liners bonded to the denture base. They characterized denture and soft liner adhesion and to determine the adhesive and/or cohesive strength of different soft tissue liners bonded to the denture base by use of a new technique and concluded that there is a significant difference in the bond strength between soft liners as function of brands (material types) and curing modes [11].

William e Wood, et al., did a study to check silicone-PMMA interfacial bond strengths. They investigated the effects of various polymerization methods and of various types of silane coupling agents on the interfacial bond strengths of Molloplast-B and of two types of heat-processed PMMA and concluded that the bond strength between a methylmethacrylate denture base and a silicone soft liner varies only slightly when either Lucitone, Lucitone 199, or polymerization in a wet or dry environment is used. Under the conditions of this study, a fresh-mixed silane coupling agent produced a distinctly superior bond strength [12].

Materials and Methods

This is a study to determine and compare the bond strength between silicone prosthetic elastomers with two different PMMA on different surface treatment. The materials and methods used in the study have been described under the following headings.

1) Fabrication of test specimen and 2) Determination of bonding strength between silicone and acrylic surface

1. Fabrication of Test Specimen

Step A – Fabrication of acrylic blocks

Rectangular shaped wax blocks with dimensions of 50mm×10mm×2mm were made [Table/Fig-1], these prepared wax blocks were then flasked in the dental flasks. After setting of the plaster the flasks were kept in dewaxing unit for dewaxing. Once dewaxing was done, flasks were opened and cold mould seal was applied, then heat cure PMMA powder and liquid were taken in a ratio according to manufacturer’s instruction, mixed and packing was done. Standard procedure was followed for curing and samples were retrieved after deflasking. A total 120 samples were fabricated, in which 60 samples were fabricated from TRAVELON and the other 60 samples from DPI [Table/Fig-1,2,3,4].

Wax sample with dimension of 50mm×10mm×2mm

Travelon acrylic resin sample with dimension of 50mm × 10mm × 2mm

DPI acrylic resin sample with dimension of 50mm×10mm×2mm

Division of the samples of (DPI) and (TRAVELON)

| Group A (DPI) | Group B (Travelon) |

|---|

| A1- acrylic sample + silicone elastomer | B1- acrylic sample + silicone elastomer |

| A2 - acrylic sample + 80 grit sand paper + silicone elastomer | B2 - acrylic sample + 80 grit sand paper + silicone elastomer |

| A3 - acrylic sample + 120 grit sand paper + silicone elastomer | B3 - acrylic sample + 120 grit sand paper + silicone elastomer |

| A4 – acrylic sample + 80 grit sand paper + gold primer + silicone elastomer | B4 – acrylic sample + 80 grit sand paper + gold primer + silicone elastomer |

| A5 – acrylic sample + 120 grit sand paper + gold primer + silicone elastomer | B5 – acrylic sample + 120 grit sand paper + gold primer + silicone elastomer |

| A6 – acrylic sample + gold primer + silicone elastomer | B6 – acrylic sample + gold primer + silicone elastomer |

Step B – Surface treatment [Table/Fig-4]

An adhesive tape was applied to define the area over which the silicone elastomer was to be bonded to the acrylic substrate. The adhesive tape was covered to an area of 25mm×10 mm leaving half the acrylic surface uncovered on to witch silicone was bonded later. Rest of the acrylic surfaces were surface treated which is as follow. Forty acrylic samples were sand papered with 80 grit sand paper (20 samples of DPI and 20 samples of travelon), next 40 acrylic samples were and papered with 120 grit sand paper (20 samples from DPI and 20 samples from travelon), primer was applied on another 20 acrylic samples and bonded to silicone elastomer (10 samples from DPI and 10 samples from travelon), and the last 20 acrylic samples were directly bonded to silicone elastomer (10 samples from DPI and 10 samples from travelon),

Step C – Obtaining the test specimen of silicone bonded to acrylic surface

Modeling wax with thickness of 2mm was attached to the all acrylic samples and were flasked, followed by dewaxing was done in dewaxing unit. Silicone elastomer base and catalyst were taken in ration according to manufactures instruction, mixed and packing was done. Standard procedure was followed for curing of each sample and test specimens were retrieved after deflasking [Table/Fig-5&6].

Silicone elastomer bonded to DPI acrylic sample

Silicone elastomer attached to TRAVELON acrylic surface

2. Determination of Bond Strength between Silicone and Acrylic Surface

Each sample was then subjected to laboratory test to determine the bond strength. Universal testing machine (HOUNSFIELD HT-400) was used in the study [Table/Fig-7]. The specimen of silicone elastomer bonded with acrylic of different surfaces was placed into universal testing machine for “PEEL TEST”. The silicone was peeled from the acrylic block from one end at a constant speed of 40mm/min. The values were measured in n/mm for each specimen. All the values obtained were tabulated and subjected to statistical analysis.

Hounsfield HT -400 universal testing machine

Results

Universal testing machine (Hounsfield HT-400) was used to check the bond strength at a crosshead speed of 40mm/minute. Bond strength was measured at every 1mm interval and the maximum value obtained was considered. Each sample was tested for peeling of silicone prosthetic elastomers from acrylic surface. Values obtained were tabulated and they were statistically analysed using individual t-test and ANNOVA test. The results obtained were tabulated in [Table/Fig-8,9,10,11,12].

The mean and standard deviation of the bond strength of silicone elastomers bonded to DPI and TRAVELON acrylic resin of different surfaces

| Groups | Mean value (n/mm)±Std. deviation |

|---|

| A1 | 1.291 ± 0.008313 |

| B1 | 1.038 ± 0.009214 |

| A2 | 0.076 ± 0.006000 |

| B2 | 0.082 ± 0.010066 |

| A3 | 0.085 ± 0.007149 |

| B3 | 0.087 ± 0.015663 |

| A4 | 2.782 ± 0.008907 |

| B4 | 2.831 ± 0.011537 |

| A5 | 2.091 ± 0.013149 |

| B5 | 2.119 ± 0.010424 |

| A6 | 4.351 ± 0.008420 |

| B6 | 4.826 ± 0.008932 |

Shows the comparison of the bond strength of silicone elastomer of control subgroup – A1 (silicone bonded directly to DPI acrylic surface) versus silicone bonded to different surfaces of DPI acrylic resin

| Group | Mean±Std. deviation | p-value |

|---|

| A1 1.291±0.008 | A2 | 0.076 ± 0.006 | 0.02 |

| A3 | 0.085 ± 0.071 | 0.02 |

| A4 | 2.782 ± 0.008 | 0.03 |

| A5 | 2.091 ± 0.013 | 0.01 |

| A6 | 4.351 ± 0.008 | 0.001 |

Shows the comparison of the bond strength of silicone elastomer of control subgroup – B1 (silicone bonded directly to TRAVELON acrylic surface) versus silicone bonded to different surfaces of TRAVELON acrylic resin

| Group | Mean±Std. deviation | p- value |

|---|

| B1 1.038±0.009 | B2 | 0.082 ± 0.010 | 0.01 |

| B3 | 0.087 ± 0.015 | 0.03 |

| B4 | 2.831 ± 0.011 | 0.02 |

| B5 | 2.119 ± 0.010 | 0.02 |

| B6 | 4.826 ± 0.008 | 0.001 |

Shows the comparison of the mean significance of bond strength between different surfaces (Subgroups) of DPI material (group A)

| A1 1.291±0.08 | A2 0.076±0.006 | A3 0.085±0.007 | A4 2.782±0.008 | A5 2.091±0.013 | A6 4.351±0.008 |

|---|

| A1 1.291±0.08 | - | 0.02 | 0.02 | 0.03 | 0.01 | 0.001 |

| A2 0.076±0.006 | 0.02 | - | 0.07 | 0.01 | 0.02 | 0.001 |

| A3 0.085±0.007 | 0.02 | 0.07 | - | 0.01 | 0.02 | 0.01 |

| A4 2.782±0.008 | 0.03 | 0.01 | 0.01 | - | 0.03 | 0.001 |

| A5 2.091±0.013 | 0.01 | 0.02 | 0.02 | 0.03 | - | 0.001 |

| A6 4.351±0.008 | 0.001 | 0.001 | 0.01 | 0.001 | 0.001 | - |

Shows the comparison of the mean significance of bond strength between different surfaces (Subgroups) of TRAVELON material (group B)

| B1 1.038±0.009 | B2 0.082±0.01 | B3 0.087±0.01 | B4 2.831±0.011 | B5 2.119±0.010 | B6 4.826±0.008 |

|---|

| B1 1.038±0.009 | - | 0.01 | 0.03 | 0.02 | 0.02 | 0.001 |

| B2 0.082±0.01 | 0.01 | - | 0.409 | 0.01 | 0.02 | 0.001 |

| B3 0.087±0.01 | 0.03 | 0.409 | - | 0.02 | 0.03 | 0.01 |

| B4 2.831±0.011 | 0.02 | 0.01 | 0.02 | - | 0.03 | 0.001 |

| B5 2.119±0.010 | 0.02 | 0.02 | 0.03 | 0.03 | - | 0.001 |

| B6 4.826±0.008 | 0.001 | 0.001 | 0.01 | 0.001 | 0.001 | - |

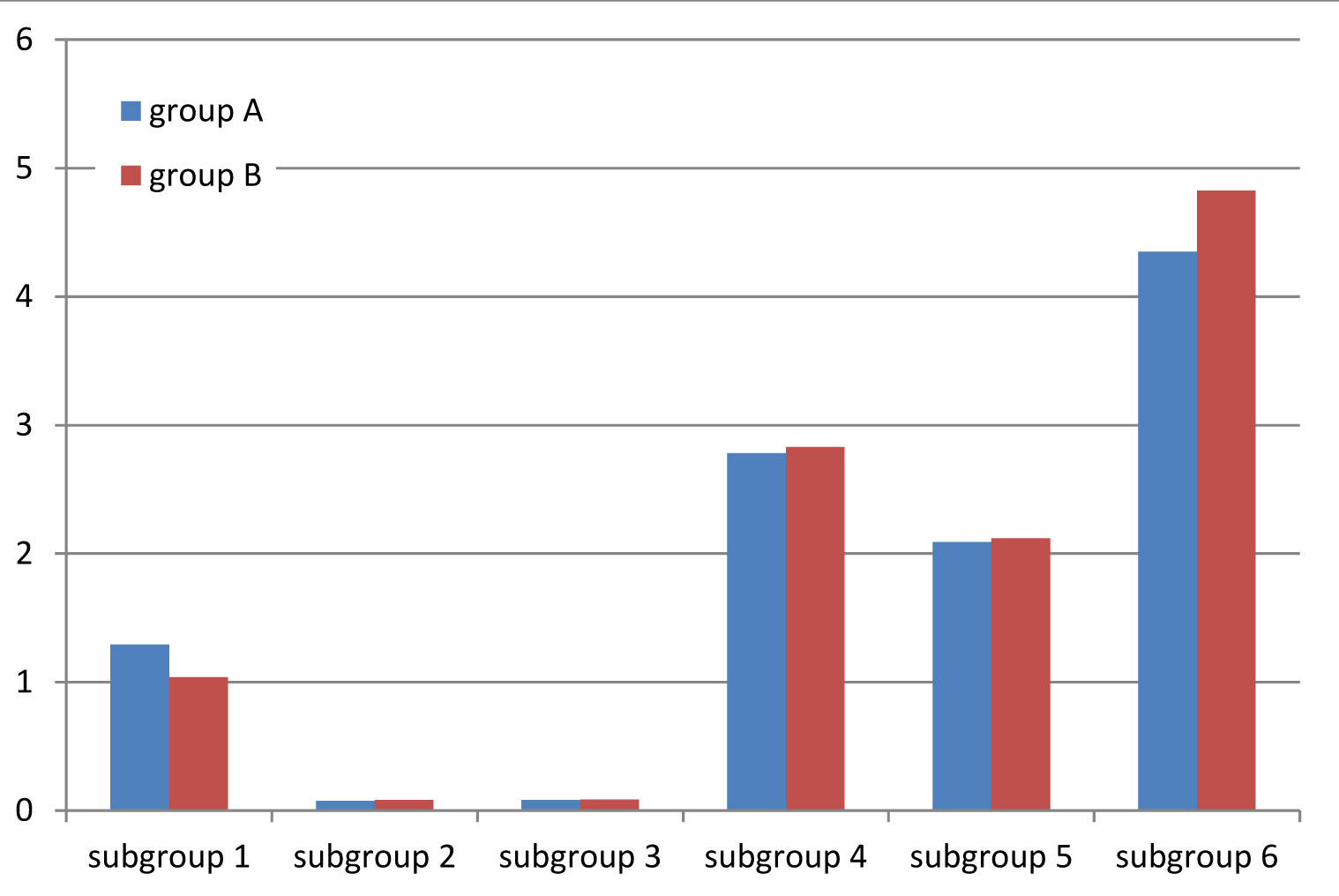

[Table/Fig-8] Show that silicone bonded to acrylic surface treated by primer showed the maximum bond strength in both in DPI (Mean 4.826 ± 0.008n/mm) and TRAVELON material. (4.351±0.0089), whereas the least bond strength values were found when the surface was treated by 120 grit sand paper that is (0.076 ±0.00 n/mm) and (0.082 ±0.01 n/mm) for DPI and TRAVELON respectively.

[Table/Fig-9] In control subgroup A1 was compared to silicone elastomer bonded to various acrylic surfaces. Results showed that, when the silicone elastomers bonded to acrylic surface with primer was highly significant (p ≤0.001) (subgroup A6), when compared to subgroup A1, whereas bond strength was found weak when acrylic surfaces were finished with 80 grit and 120 grit sand paper. It is also found that there was no statistical significant difference in the bond strength of sand papered acrylic surfaces with and without primer application (p ≤0.05).

[Table/Fig-10] In control subgroup B1 was compared to silicone elastomer bonded to various acrylic surfaces. Results showed that, when the silicone elastomers bonded to acrylic surface with primer was highly significant (p ≤0.001) (subgroup B6), when compared to subgroup B1, whereas bond strength was found weak when acrylic surfaces were finished with 80 grit and 120 grit sand paper. It is also found that there was no statistical significant difference in the bond strength of sand papered acrylic surfaces with and without primer application (p ≤0.05).

[Table/Fig-11] Show highest bond strength was seen when the silicone elastomer was bonded to acrylic surface with primer without sand papering compared to any other surface. Though the 80 grit sand papered acrylic surfaces with primer had significant difference (p>0.001) in the bond strength, with 120 grit sand papered acrylic surfaces with primer, the bond strength was less than that of acrylic surface with primer without sand papering. But there was no statistical significant difference (p>0.05) in the bond strength of the 80 grit and 120 grit sand papered acrylic surfaces without primer.

[Table/Fig-12] Show highest bond strength was seen when the silicone elastomer was bonded to acrylic surface with primer without sand papering compared to any other surface. Though the 80 grit sand papered acrylic surfaces with primer had significant difference (p>0.001) in the bond strength, with 120 grit sand papered acrylic surfaces with primer, the bond strength was less than that of acrylic surface with primer without sand papering. But there was no statistical significant difference (p>0.05) in the bond strength of the 80 grit and 120 grit sand papered acrylic surfaces without primer.

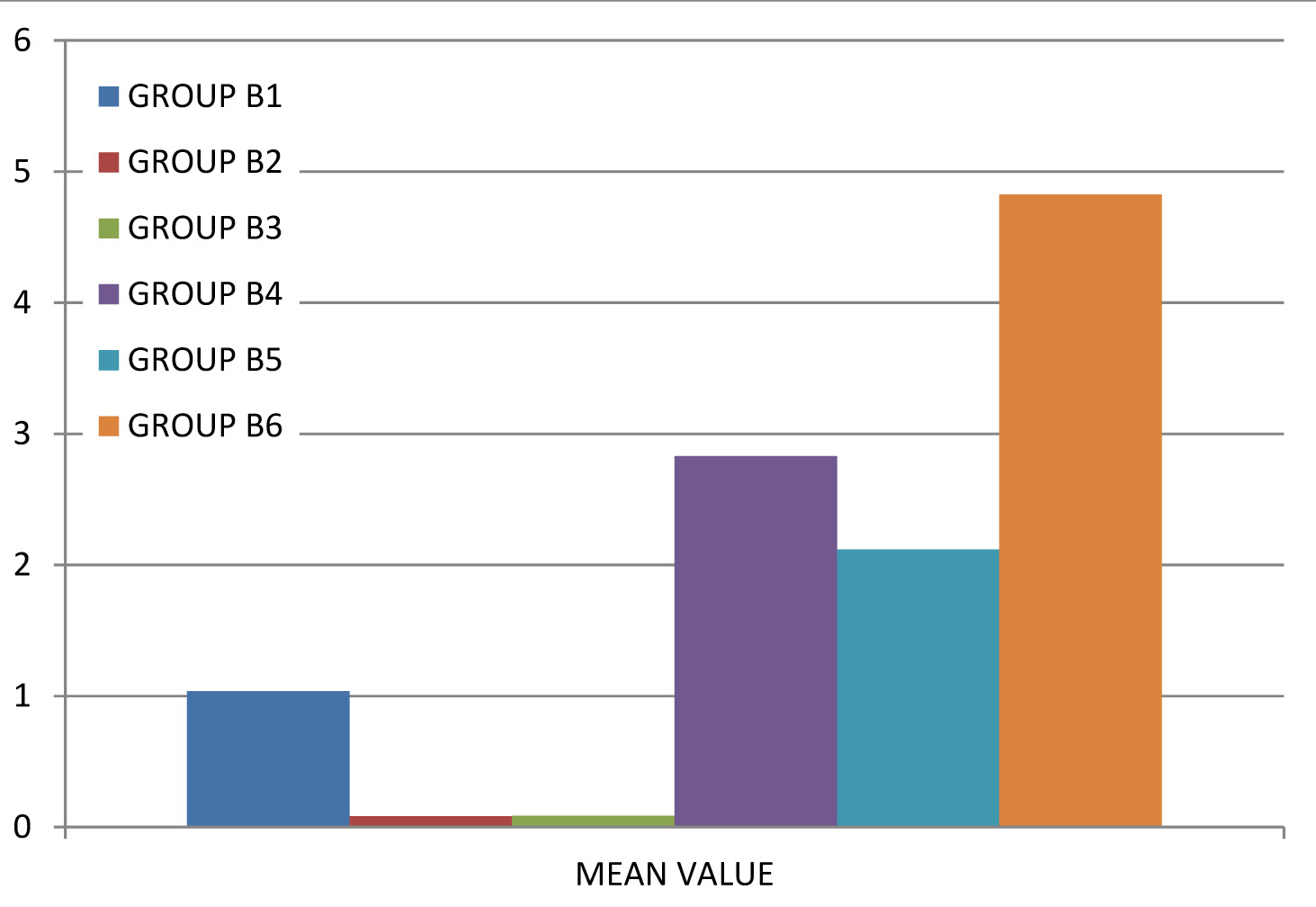

[Table/Fig-13] Result explains that subgroup B6 shows highest mean value of 4.826n/mm followed by subgroup A6 with mean value of 4.351n/mm. Whereas least mean value was seen with the subgroup A2 that is 0.076n/mm followed by subgroup B2 with mean value of 0.082 n/mm.

Shows comparison of mean values for group A and group B and their subgroups

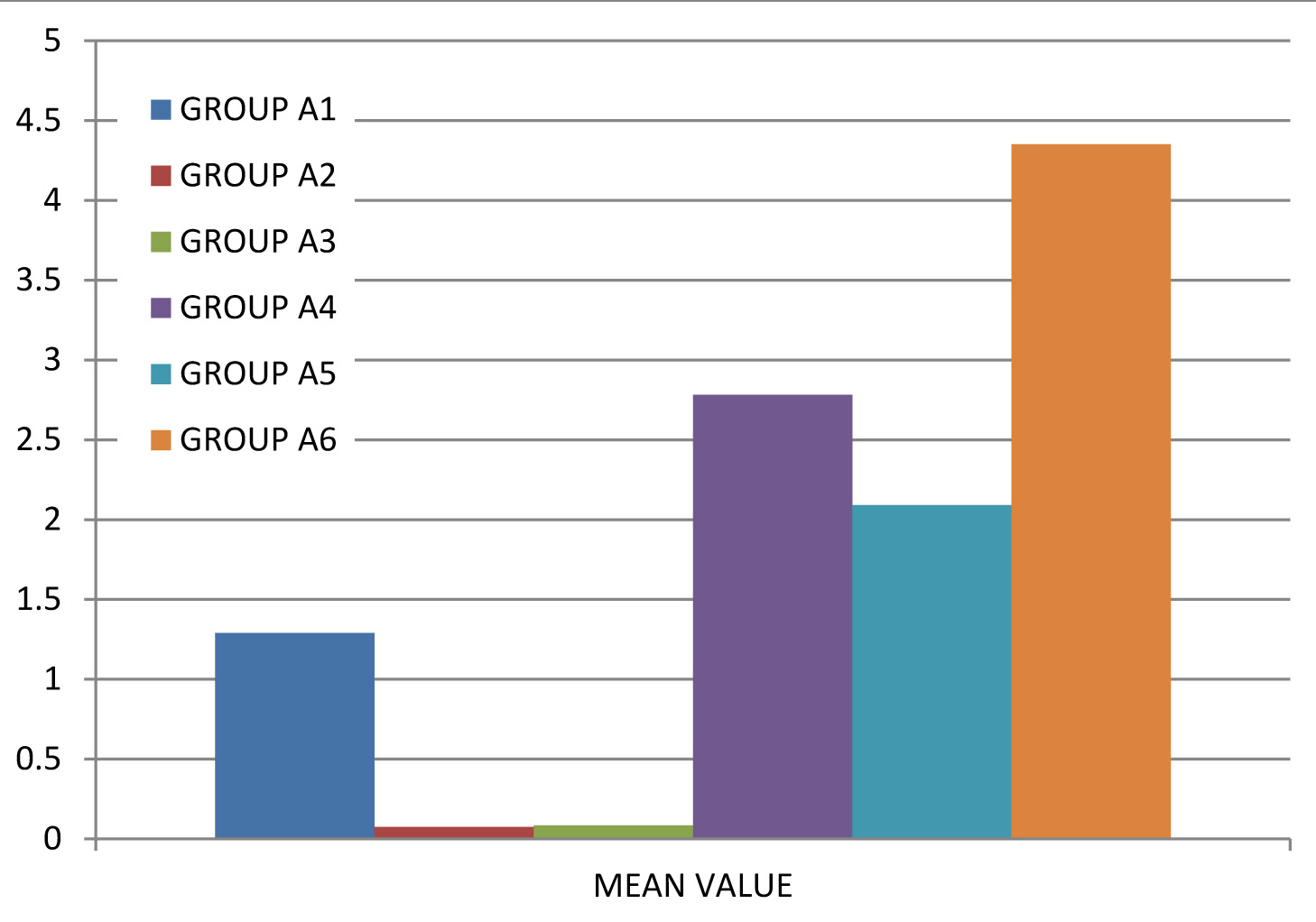

[Table/Fig-14] Demonstrates Result showed that the bond strength was highest when subgroup A1 was compared to subgroup A6 that is 4.351 n/mm, whereas the bond strength was weak when subgroup A1 was compared to subgroup A2 that is 0.076 n/mm.

Shows comparison of control subgroup A1 (silicone elastomer bonded to acrylic surface without any surface modification) to silicone elastomer bonded to all other acrylic surfaces (DPI)

[Table/Fig-15] Result showed that the bond strength was highest when subgroup B1 was compared to subgroup B6 that is 4.826 n/mm, whereas the bond strength was weak when subgroup B1 was compared to subgroup B2 that is 0.082 n/mm.

Shows comparison of control subgroup B1 (silicone elastomer bonded to acrylic surface without any surface modification) to silicone elastomer bonded to all other acrylic surfaces (TRAVELON)

Discussion

Maxilofacial prosthetics is the branch of dentistry that provides prostheses or devices to treat or restore tissues of the stomatognathic system and associated facial structures that have been affected by disease, injury, surgery, or congenital defect, to provide all possible function and esthetics [2]. Gold, silver, leather, vulcanized rubber, gelatin, latex, polyvinyl chloride, polyurethane, chlorinated polyethylene, and silphenylenes have all been used at various stages of evolution of materials for such prostheses, but the drawback of these materials are abrasion of skin, difficulty to match edges of skin to prosthesis and increased bulk and weight of prostheses. In contrast silicone is biocompatible and bio-durable. Silicone is easy to manipulate with adequate working time and has got good color stability. Its physical properties of relevance include hardness, high tear resistance and reliable bonding to acrylic substructures which are frequently used along with them. However, they undergo wear, degrade and start discoloring within 2 years. They can tear easily if not handled properly and can be difficult to maintain and keep clean. Silicone elastomers are used in the fabrication of artificial external body parts such as ears, nose and eyes.

Though, aesthetically silicone elastomer is best suitable in fabrication of maxillofacial reconstruction with acrylic resin sub-structure but the bonding of the same is the question while fabricating the prosthesis.

The result showed that the bond strength of silicone elastomer bonded to acrylic resin was highest when only primer was used directly on the acrylic surface as a bonding agent between them as compared to all other surface.

Primers change the surface of substrate to relatively organic surface, to allow the adhesive better wetting and potential covalent bonding between substrate and adhesive. The usual reactive groups on the silane that promote adhesion are hydrolyzable organic groups, like alkoxy or acetoxysilanes. Hence, it increases the mechanical inter-locking between silicone and acrylic surface.

Similar study has been carried out by Robert M Taft et al., to check the effect of primers and surface characteristics on the adhesion-in-peel force of silicone elastomer bonded to resin materials. They used dow Corning 1205 primer and dow Corning S-2260 primer and concluded that A-1205 primer showed stronger bond strength regardless which type of resin or surface preparation was used [13]. Effect of sand papering the acrylic surface of DPI and TRAVELON (both 80 grit sand papering and 120 grit sand papering) showed weak bond strength when compared control group (where silicone bonded to acrylic surface without any modification) because of the smoother acrylic surface after 80 and 120 grit sand papering, Which will reduce the micro-mechanical inter-locking between silicone and acrylic.

Similar study has been carried out by Marcela Filie Haddad et al., did a study to check the bond strength between acrylic resin and maxillofacial silicone. They used different primers and surface modification (scratch) to check the effect of bond strength and concluded that use of primer increased the bond strength but use of primer along with the surface modification (scratch) has weakened the bond strength between silicone elastomer and acrylic [14].

Comparing the bond strength between silicone prosthetic elastomer and two different acrylic materials (DPI and TRAVELON), the higher bond strength was noticed with TRAVELON than DPI acrylic material.

Similar study has been done by MoodhySaleh Al-Athe, et al., did a study to check the Bond Strength of Resilient Lining Materials to Various Denture Base Resins and concluded that the bond strength of Novus was dependent on the denture base material, and was greatest with TS 1195 [15].

Whereas the weak bond strength was found when DPI acrylic surface was sand papered with 80 grit sand paper and silicone elastomer was bonded to it showed the weakest bond strength as compared to all other silicone elastomer and acrylic interface.

Conclusion

This is an in vitro study conducted to determine and compare the bond strength of silicone prosthetic elastomers with two different polymethylmethacrylate bonded to different surface treatment. Universal testing machine (Hounsfield HT-400) was used to check the bond strength at a crosshead speed of 40mm/minute. Bond strength was measured at every 1mm interval and the maximum value obtained was considered. The bond strength of silicone elastomer to acrylic resin was higher when primer was used on the acrylic surface.The bond strength of silicone elastomer to acrylic resin was more with travelon resin when compared to DPI resin Whereas, when silicone bonded to acrylic surface with sand papering, showed less bond strength. But when silicone elastomer bonded to acrylic resin with sand papering and primer showed higher bond strength.

[1]. Glosary Of Prosthodontic Terms – 8 [Google Scholar]

[2]. Sethi Tania, Kheur Mohit, Silicone elastomers and their role in maxillofacial prosthetic rehabilitationInt J Bas And App Med Sc 2012 2:263-66. [Google Scholar]

[3]. Shetty Uttam Sadashiv, Guttal Satyabodh Shesharaj, Evaluation of bonding efficiency between facial silicone and acrylic resin using different bonding agents and surface alterationsJ Adv Prosth 2012 4:121-26. [Google Scholar]

[4]. Polyzois Gregory L, Dr Dent Frangou Mary J, Bonding of silicone Prosthetic elastomers to three different denture resinsInt J Prosthet 2002 15:535-38. [Google Scholar]

[5]. Kantola Rosita, Lassila Lippo, Vallittu Pekka, Adhesion of maxillofacial silicone elastomer to a fiber-reinforced composite resin frameworkInt J Prosthet 2011 24:582-88. [Google Scholar]

[6]. Mcmordie Roy, King Gordon E, Effect of primer on bonding of silicone to denture base materialJ prosthet dent 1989 61:636-39. [Google Scholar]

[7]. Al-Athel Moodhy S, Jagger Robert G, Effect of test method on the bond strength of a silicone resilient denture lining materialJ prosthet dent 1996 76:535-40. [Google Scholar]

[8]. Kutay Omer, Comparison of tensile and peel bond strengths of resilient linersJ prosthet dent 1994 71:525-31. [Google Scholar]

[9]. Khan Zafrulla, Martin Jack, Collard Stephen, Adhesion characteristics of visible light-cured denture base material bonded to resilient lining materialsJ Prosthet Dent 1989 62:196-200. [Google Scholar]

[10]. Dootz ER, Koran A, Craig RG, Physical property comparison of 11 soft denture lining materials as a function of accelerated agingJ Prosthet Dent 1993 69:114-19. [Google Scholar]

[11]. Emmer Thomas J, Vaidyanathan Jaylaxmi, Vaidyanathan Ttritala K, Bond strength of permanent soft denture liners bonded to dentureBase J Prosthet Dent 1995 74:595-601. [Google Scholar]

[12]. Wood William E, Johnson Dean L, Duncanson Manville G, Variables affecting silicone polymethylmethacrylate interfacial bond strengthsJ Prosthodont 1993 2:13-18. [Google Scholar]

[13]. Taft Robert M, Cameron Stephen M, Knudson Rodney C, Runyan Dennis A, The effect of primers and surface characteristics on the adhesion-in-peel force of silicone elastomers bonded to resin materialsJ Prosth Dent 1996 76:515-18. [Google Scholar]

[14]. Marcela Filié Haddad, Marcelo Coelho Goiato, Daniela Micheline Dos Santos, Nádia De MarchiCrepaldi, Aldiéris Alves Pesqueira, Lisiane Cristina Bannwart, Bond strength between acrylic resin and maxillofacial siliconeJ Appl Oral Sci 2012 20:649-54. [Google Scholar]

[15]. Moodhy Saleh Al-Athei, Robert Grant jagger, Bond strength of resilient lining materials to various denture base resinsInt j Prosthodot 1996 9:167-70. [Google Scholar]