The first stage of the comprehensive fixed Orthodontic treatment includes leveling and aligning. The initial archwires for alignment should have good working range which delivers light and continuous forces for the efficient tooth movement. Since the introduction of nickel titanium alloy in early 1970s into orthodontics [1], they have gained substantial popularity for clinical application as initial aligning wires. At present two types of nickel-titanium alloy wires are commercially available. The original Nitinol wires are primarily in the martensitic phase at room temperature, the newer NiTi wires have an austenitic grain structure and 1.6 times greater springback than Nitinol. The properties of the superelastic NiTi wire are unique which includes the phenomenon of shape memory, greater spring back and flexibility allowing large elastic deflections with minimum load [2]. Further when compared with Nitinol, the NiTi wires are also 36% less rigid at 80° of activation and stress relaxation is not time dependent [1,2]. The advantageous mechanical properties of nickel titanium alloy wires and their comparatively high cost have compelled many clinicians to recycle these wires [3].

A survey conducted by Buckthal revealed that about 52% of the orthodontists who use nickel-titanium wires recycle them [4]. Since then various studies [1,3,5,5–11] have been conducted to determine the effect of various types of recycling procedures on the mechanical and surface properties of the Nitinol or NiTi wires [Table/Fig-1].

Commercially there are innumerable wire brands in the market supplying superelastic NiTi. A review of literature yields that none of the studies mentioned in the literature evaluated the physical and mechanical properties of superelastic NiTi after clinical usage and recycling of these wires. The quantification of the surface changes produced by recycling methods is also missing in these studies [1,3,5,8] [Table/Fig-1].

The purpose of the present study was therefore to determine the cumulative mechanical and physical effects of recycling of four types of different commercially available superelastic NiTi alloy after clinical usage in oral environment for a period of three months followed by autoclaving.

Materials and Methods

Design of the study: The present in-vitro study with a two armed, double blinded randomized stratified block design where experimental samples and control group of sample wires were compared.

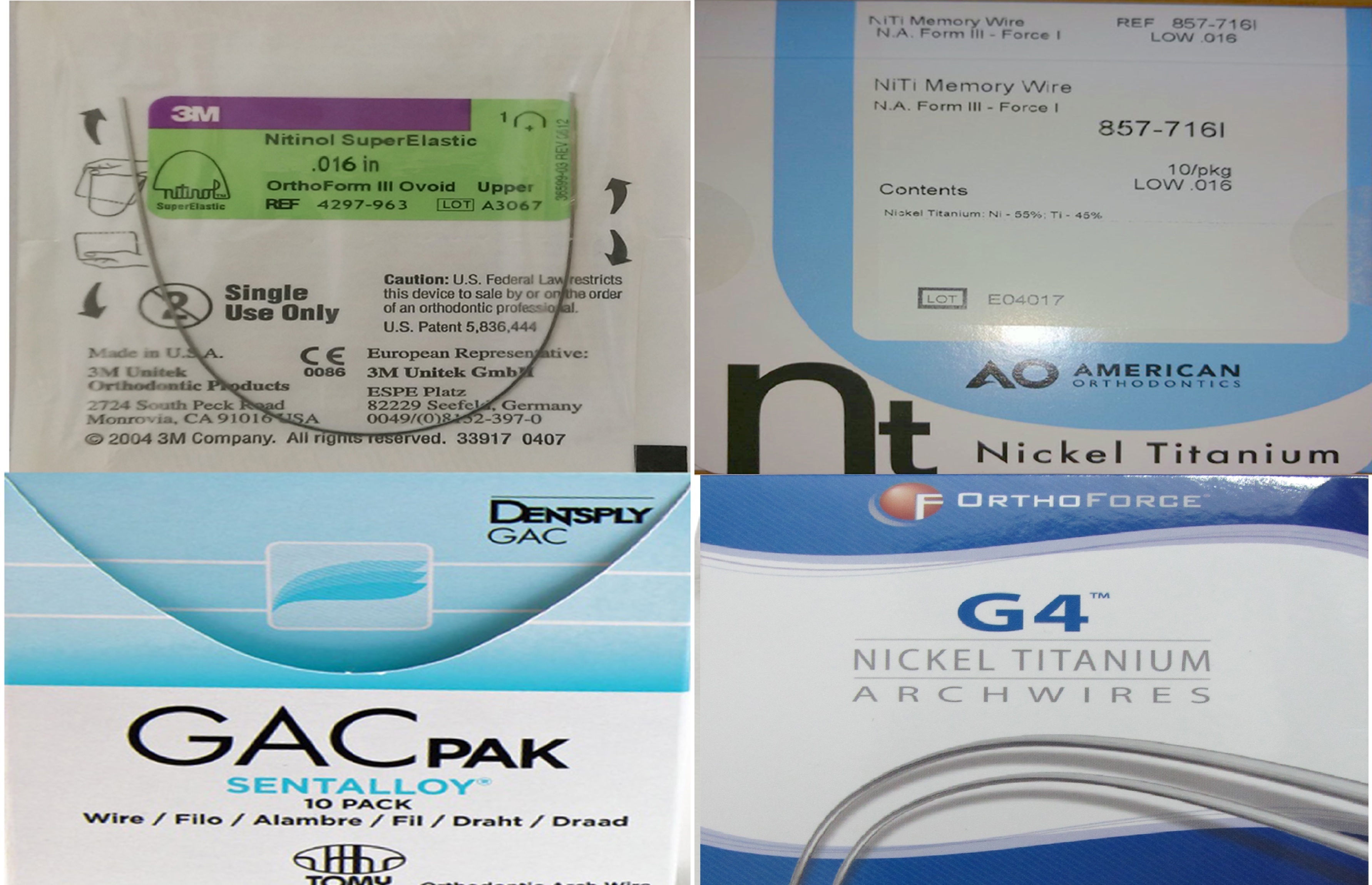

This study was conducted at the Department of Orthodontics and Dentofacial Orthopedics, Narayana Dental College, Nellore, Andhra Pradesh, India, in collaboration with Department of Physics, Osmonia University, Hyderabad and The Micro, Small and Medium Enterprises (MSME) testing center, Hyderabad, Telangana, India. Based on the pilot study findings that initially included two samples of wires in each group, the final sample size was determined to be 64 by taking 80% power of the study and 5% margin of error (1-ß). The sample size included the archwires utilized in the pilot study and a total of 80 samples were included in this study. The superelastic NiTi wires from four different manufactures were divided into four groups as follows:

Group I- GAC (McMinnville, USA).

Group II- 3M Company (California, USA).

Group III- G&H Company (Franklin, USA).

Group IV- American Orthodontics (AO) (Sheboygan, USA).

The lower arch wires with standard arch shapes of orthoform III or equivalent as supplied by the individual manufacturers were utilized in the study. Each group comprised of 20 samples of super elastic ‘NiTi’ 0.016" wire [Table/Fig-2]. A sample of 10 wires in each group was sub grouped as Control or unused wires (C) and the remaining 10 samples of wire from each group were designated as experimental or Test subgroup (T). These test samples were placed during initial and leveling phase for the patients registered for the orthodontic treatment.

Group of wires used in the study.

The procedure was explained to the patient and an informed consent was obtained. The study design was approved by the Institutional ethical committee (Lr No.1045/A9/MDS/Diss/2013-2014/dated 27-03-2014).

The clinical phase of the study included 40 patients between 12-18 years of age. The inclusion criteria being the presence of complete set of permanent mandibular teeth except third molars with anterior symmetrical and uniform crowding with Little’s irregularity index score of 4mm to 6mm and with complete physical and mental health [12]. The patients with posterior crowding, severe anterior deep bite and crossbite were excluded from the study. All the patients who met the inclusion criteria were bonded with Pre-Adjusted Edgewise (PAE) 0.022” slot MBT prescription appliance. After the placement of archwire, the patients were given standard instructions and elastic modules were changed every month. After 3 months of alignment phase, the wires were retrieved carefully by holding at the premolar region thus avoiding the handling of the archwire at the midline [Table/Fig-3]. The retrieved wires were then rinsed and cleaned with deionised water and subjected to heat sterilization by using autoclave at 121°C (250°F) at a pressure of 15 to 20 psi for 20 minutes. After sterilization, the retrieved wires were packed in an airtight cover and subjected for testing.

Clinical handling of the archwires. The archwires are placed in the patients exhibiting a lower arch with mild crowding (Littlle’s index<4mm-6mm.). The archwires are removed by holding at the premolar area.

In each experimental group, eight samples were utilized for testing the mechanical and physical properties whereas the other two sample were utilized for evaluation of surface topography.

A two stage systematic sampling allotment was followed. In the first stage, systematic distribution between control group and experimental group was done followed by the second stage where sampling allotment between operators who placed the archwires and each of the experimental groups was done.

Tensile Testing: The tensile properties were measured with Instron universal testing machine (Model-2006, Instron Corp, Canton, Massachusetts, USA), the machine was equipped with a 250Kg load cell and a full-scale sensitivity of 0 to 200gm [Table/Fig-4]. The distal ends of the wire were cut and the wire specimen of 80 mm length spreading equally across the midline was tested for the properties. The span of the wire between the cross-heads was standardized as 20mm. The loading was done at a crosshead speed of 1mm/min at 50gm. The final load required to break the wire was noted. This gives the Ultimate Tensile Strength (UTS) or breaking strength of the wire. A total of 64 wire specimens were tested for the physical properties. In this study the cross–sectional area of specimen is 0.016 inch super elastic NiTi and the maximum load applied is 2450 Newtons. The UTS is equated to the braking strength of the wire. This is calculated by the load required to break the wire for a given cross-sectional area specimen of the wire sample.

Instron universal testing machine for measuring the ultimate tensile strength of the wires.

Surface Topography: Scanning Electron Microscopy (Model-Sigma 300, Zeiss Corporation, Oberkochen, Germany) was used to study the surface topography of the wires. NiTi archwire from the unused and recycled group were assessed qualitatively with the SEM at three different magnifications [Table/Fig-5]. Two wire specimens from each group were utilized for study of surface topography. For the SEM evaluation, 1-inch segment of the wire was taken from the midline in all the groups. A metallic pellet was used as a platform for the scanning SEM. The wire segment under observation was glued to an adhesive pad attached to metal pellet. The surface was scanned and viewed on the monitor at different magnifications of 100×, 500× and 1000× and the representative micrographs of the studied sample were obtained.

Scanning electron microscope for measuring surface roughness.

The surface porosity was analyzed by the method described by DeHoff RT [13]. A standard grid with each square of 1mm was superimposed with 1:1 magnification on the digital photomicrographs at 500X magnification using Adobe Photo-shop-7 (Adobe photosystems). The 1 mm grid was again magnified and equally divided into 500 pixels. The readings obtained in pixels were transformed into millimeters (1pixel/each = 0.0394 mm). Thus the measurements could be read accurately and precisely in millimeters up to the second decimal point. The line intersect count (PL) was obtained from this scanned grid. The number of intersections made by the surface irregularities such as porosities and elevations were counted on the scanned horizontal lines of the grid [Table/Fig-6]. A total length of the lines scanned was estimated to 1000mm. The surface area in unit volume (Sv) was then calculated by utilizing the following relations: PL = 1/2 Sv OR Sv = 2 PL.

Grid method for measurement of line intersection (Pl) count and quantification of surface roughness.

Statistical Analysis

The values of ultimate tensile strength and surface roughness (Pl count) of Unused and Post recycled wires separately for all the groups were tabulated utilizing Microsoft Excel work sheet 2010. The data was subjected to statistical analysis using SPSS 16 package (Statistical Package for the Social Sciences, IBM Corporation, 2009). Student’s paired ‘t’-test was used to compare the difference in ultimate strength and surface roughness of Unused and Post recycled wires in each group. One way ANOVA test is used to test the significant difference within and in between the groups of Control and Experimental wires followed by Post Hoc Tukey test.

Results

Ultimate Tensile Strength: The results showed that the ultimate tensile strength of the As Received (T1) wires of all the four groups were significantly higher than the Recycled wires (T2). The tensile strength of various nickel-titanium wires differ according to their composition and manufacturing processes. In the unused group, G & H (Group III) (1511.75 Mpa) had the greatest tensile strength and all the wires showed significant change in UTS after recycling [Table/Fig-7]. The highest difference between control and experimental wires Δ25% (1407.31MPa and 1053.55) was seen in Group I (GAC). This was followed by Δ22% (1393.68 MPa and 1080.54MPa) in Group II (3M) wires, Δ 21 % (1401.99 MPa to1106.83 MPa) in AO (Group IV) and least Δ15% (1511.75 MPa and 1282.19 Mpa) in Group III wires (G & H group).

Paired Student’s t- test for comparison of ultimate tensile strength of unused wires and recycled wires within each group.

| GROUP | n | Mean ±S.D. | S.E. | t- value | p-value |

|---|

| GROUP I-GAC | Unused | 8 | 1407.31 ± 11.63 | 4.11 | 7.433 | 0.0001** |

| Recycled | 8 | 1053.55 ± 128.3 | 45.37 |

| GROUP II-3M | Unused | 8 | 1393.68 ± 19.81 | 6.60 | 6.314 | 0.0002** |

| Recycled | 8 | 1080.54 ± 138.5 | 46.17 |

| GROUP III-G &H | Unused | 8 | 1511.75 ± 21.03 | 7.01 | 5.496 | 0.0001** |

| Recycled | 8 | 1282.19 ± 111.8 | 37.28 |

| GROUP IV-AO | Unused | 8 | 1401.99 ± 19.86 | 6.62 | 5.384 | 0.0015** |

| Recycled | 8 | 1106.83± 175.5 | 58.51 |

SD-Standard Deviation; SE- Standard Error of mean;

*p<0.05; Significant; **p<0.001; highly significant

One way ANOVA test with Post Hoc Tukey was performed to check whether there is any significant difference between groups before recycling and after recycling [Table/Fig-8]. A statistically significant difference in the ultimate tensile strength value was found between the unused wires of all groups (p<0.001) as well as after recycling of the wires (p=0.008).

One way ANOVA and Post Hoc Tukey test for comparison of ultimate tensile strength between and within groups.

| GROUP | Mean ±S.D. | S.E. | t- value | p-value |

|---|

| ANOVA | Unused (T1) | Between Groups | 3 | 79.696 | 0.000** |

| Within Groups | 31 |

| Total | 34 |

| Post Recycled (T2) | Between Groups | 3 | 4.731 | 0.008** |

| Within Groups | 31 |

| Total | 34 |

| GROUPS | Mean Difference | Std. Error | p-value |

| UNUSED WIRES(T1) | GROUP I-GAC | GROUP II-3M | 13.63 | 9.06 | 0.447 |

| GROUP III-G&H | -104.43 | 9.06 | 0.00** |

| GROUP IV-AO | 5.31 | 9.06 | 0.935 |

| GROUP II-3M | GROUP III-G&H | -118.06 | 8.79 | 0.000* |

| GROUP IV-AO | -8.31 | 8.79 | 0.781 |

| GROUP III-G&H | GROUP IV-AO | 109.75* | 8.79 | 0.000** |

| POST RECYLING (T2) | GROUP I-GAC | GROUP II-3M | -26.98 | 68.46 | .979 |

| GROUP III-G&H | -228.63 | 68.46 | .011 |

| GROUP IV-AO | -53.27 | 68.46 | .864 |

| GROUP II-3M | GROUP III-G&H | -201.65 | 66.41 | .024* |

| GROUP IV-AO | -26.28 | 66.41 | .979 |

| GROUP III-G&H | GROUP IV-AO | 175.36 | 66.41 | .051* |

Post Hoc Tukey HSD *p<0.05; Significant; **p<0.001; Highly significant

Surface Roughness: The highest PL count in unused groups was found in 3M group (0.410) (group II) of wires and there was significant difference in surface roughness in between Unused wires and recycled wires in all the groups with ‘p’ values < 0.001 for all the groups evaluated in the study. Thus the wires evaluated for surface topography exhibited definite increase in surface roughness after recycling [Table/Fig-9].

Paired Student’s t-test for comparison of surface roughness (Pl count) of unused wires and recycled wires within each group.

| GROUP | Mean ±S.D. | S.E. | t- value | p-value |

|---|

| GROUP I-GAC | Unused | 0.409 ± 0.021 | 0.0066 | 3.9082 | 0.001* |

| Recycled | 0.444 ± 0.019 | 0.0060 |

| GROUP II-3M | Unused | 0.410 ± 0.029 | 0.0091 | 4.3773 | <0.001** |

| Recycled | 0.463 ± 0.025 | 0.0079 |

| GROUP III-G &H | Unused | 0.369 ± 0.033 | 0.0104 | 5.6453 | <0.001** |

| Recycled | 0.444 ± 0.026 | 0.0082 |

| GROUP IV-AO | Unused | 0.354 ± 0.032 | 0.0101 | 4.9532 | <0.001** |

| Recycled | 0.426 ± 0.033 | 0.0104 |

SD- standard Deviation; SE- Standard Error of mean;

*p<0.05; Significant; **p<0.001; highly significant

Similarly surface roughness is compared within the groups and between the groups before and after recycling using one way ANOVA variant test followed by Post Hoc Tukey test. The analysis showed a highly significant difference between archwires in unused groups and the wires of recycled groups. There was significant difference in surface roughness between GAC group (Group I), G & H (Group III) and AO group (group IV) [Table/Fig-10].

One way ANOVA and Post Hoc Tukey test for comparison of surface roughness (Pl count) between and within groups.

| GROUP | Mean ±S.D. | t- value | p-value |

|---|

| ANOVA | Unused (T1) | Between Groups | 8.366 | < 0.001**. |

| Within Groups |

| Total |

| Post Recycled (T2) | Between Groups | 3.104 | 0.040* |

| Within Groups |

| Total |

| GROUPS | Mean Difference | p-value |

| UNUSED WIRES(T1) | GROUP I-GAC | GROUP II – 3M | -0.001 | 1.000 |

| GROUP III-G&H | 0.040* | 0.032* |

| GROUP IV - AO | 0.054 | 0.002* |

| GROUP II-3M | GROUP III-G&H | 0.041* | 0.027* |

| GROUP IV-AO | 0.055* | 0.002* |

| GROUP III-G&H | GROUP IV-AO | 0.014 | 0.723 |

| POST RECYLING (T2) | GROUP I-GAC | GROUP II-3M | -0.018 | 0.434 |

| GROUP IIIG&H | 0.000 | 1.000 |

| GROUP IV-AO | 0.018 | 0.434 |

| GROUP II-3M | GROUP III-G&H | 0.018 | 0.434 |

| GROUP IV-AO | .037 | 0.022* |

| GROUP III-G&H | GROUP IV - AO | .018 | 0.434 |

Post Hoc Tukey HSD *p<0.05; Significant; **p<0.001; Highly significant

Discussion

The superelastic nitinol wires or austenite stabilised nitinol wires undergo a phase transformation in their crystal structure when cooled from the stronger, high temperature form (Austenite) to the weaker, low temperature form (Martensite). This inherent phase transformation is the basis for the unique properties of these alloys-in particular, Shape Memory and Superelasticity [14]. Nickel Titanium alloy (NiTi) wires display excellent resilience and low load–deflection rates [14], however high cost has hindered their universal appeal. As a consequence of both cost and retention of the moderately acceptable elastic properties after clinical usage, prompted the clinicians to reuse the archwires after recycling. The wires are said to be recycled when there is repeated exposure of the wire to mechanical stresses and elements of the oral environment for several weeks or months as well as sterilization between uses [1].

The present in-vitro study differed from the previous studies in that it compared and evaluated the properties of four different commercially available superelastic NiTi arch wires after clinical recycling followed by autoclave method of sterilization.

Ultimate Tensile Strength: These earlier studies have focused on the effects of mechanical properties and phase transformation of the wires under given in-vitro conditions [1,3,5,6–11]. The key aspect that extricates oral cavity from in-vitro media is the presence of oral flora and their byproducts as well as accumulation of plaque on the material in the oral cavity. The intricate intraoral environmental ambiance cannot be simulated in in-vitro setup, most of which involve exposure of materials to artificial saliva, various electrolytes, water and other known media. The conclusions drawn from these in-vitro or simulated in-vivo environment studies cannot be applied to clinical situations and hence, do not carry greater clinical significance [15]. The present study also suffers from similar limitation.

The presence of significant change in mechanical properties found in the present study coincides with the results of Kapila S et al., [1] and Kapila S et al., [6]. Devaprasad AP et al., also displayed significant decrease of 5% in the ultimate tensile strength between the unused wire and the 6-month retrieved wire of the two groups [16]. However, the effects of autoclaving were not observed in their study. The results obtained in the present study are not in concordance with the studies of Mayhew and Kusy [3] and the study conducted by Sung Ho Lee and Young II Chang [8] comparing Optimalloy and Sentalloy. Another study by Sung Ho Lee and Young II [17], where martensitic nickel-titanium wires demonstrated significant changes in 3-point bending properties and the characteristics of the stress-strain curve by autoclave sterilization, but austenitic nickel titanium wires demonstrated no statistically significant change.

Surface Topography: The SEM observational studies of the four groups of wires showed increased pitting and attachment of debris on the surface of the wires [Table/Fig-11]. The results of this study were in concordance with the findings of earlier study conducted by Sung Ho Lee and Young II Chang [8] on Ni-Ti and Optimalloy wires that exhibited more indentations and pitting after recycling indicating surface corrosion. Harris reported surface interruption, oxidation pitting, and decreased performance of Nitinol in an in-vivo evaluation [18]. The effect of autoclave sterilization in the present study might have further deterred the surface properties. Nevertheless, Edie reported no obvious visible difference because of surface corrosion in a clinical test [15]. The deterioration of surface properties though affect frictional resistance of any orthodontic wire, this has no clinical relevance as far as NiTi wire is concerned. This degradation of surface properties may lead to decreased performance of other intended mechanical properties. The present study has revealed both the qualitative and quantitative changes in surface topography.

Comparison of surface roughness of unused and post recycled wires of all groups (magnification; 500X).

The earlier studies compared the deflection characteristics of superelastic wires under loading and deloading after clinical recycling followed by chemical sterilization or dry heat [1,6]. One in-vitro study compared the effects of autoclaving method of sterilization with cold sterilization [7]. The present study is unique because it has considered clinical recycling as well as autoclave method of sterilization in superelastic NiTi wires.

The difference in the mean tensile strength of unused and recycled wires ranged from 15% to 25% in different groups in this study. The marked reduction in the mechanical properties in our study may be attributed to both clinical degradation and recycling process by autoclaving.

This implies that the recycled NiTi wires lose some of their springback characteristics and may demonstrate work-hardening characteristics probably caused by the amassed effects of the masticatory forces and changes in intraoral temperatures. These amendments in the springback property of NiTi wires may advocate that recycled NiTi wires require frequent activations or hastier archwire changes than would normally be anticipated clinically with previously unused wires. Even though there are statistically significant changes in properties of NiTi, those changes may not be clinically adequate to alter the tooth movement.

Okamoto et al., scrutinized the thermal expansion curves of austenite nitinol wires and found no remarkable changes were found when the wires were put through hot and cold cyclic treatment below 350°C [19]. In addition, comparing the results of the present study with that of the earlier studies, it is clear that the the effects of combined clinical recycling followed by autoclaving are more pronounced than the effects of clinical use. Since the temperature during steam sterilization in the study did not exceed 121°C for a total of 20 minutes, its impact on wire properties may have been relatively minimal.

Limitation

The main limitation of the study was that it was an in-vitro study and only the tensile properties were considered.

Given that few studies are performed on the recycling of superelastic NiTi wires after clinical recycling and autoclave method of sterilization, more research in this field are recommended, particularly evaluating the effect of autoclaving on phase transformations, loading and deloading characteristics of these Super elastic Ni Ti wires. Further, this study has not considered the effects of clinical recycling and that of autoclaving separately.

Conclusion

Under the limitations of the current study we can conclude from this study that:

Autoclave sterilization and clinical reusage can decrease tensile properties of the super elastic Ni-Ti wires.

Autoclave sterilization following clinical recycling can mitigate the surface topography of the super elastic Ni-Ti wires.

According to the findings of this study; it is not possible to recycle and autoclave superelastic Ni-Ti wires without significant reduction in their tensile properties and degradation of surface properties. Clinically, the present results of the study suggest that orthodontist should, as much as possible, avoid recycling and reuse of the archwires as the efficiency is decreased.

SD-Standard Deviation; SE- Standard Error of mean;

*p<0.05; Significant; **p<0.001; highly significant

Post Hoc Tukey HSD *p<0.05; Significant; **p<0.001; Highly significant

SD- standard Deviation; SE- Standard Error of mean;

*p<0.05; Significant; **p<0.001; highly significant

Post Hoc Tukey HSD *p<0.05; Significant; **p<0.001; Highly significant